When the city of Whitefish, Montana, needed a major upgrade of its wastewater treatment plant, it turned to Flathead Electric Cooperative for ideas. The result is a modern, more reliable facility built to handle population growth while using less electricity and cutting power costs by about $34,000 a year.

“Bring me every school kid in the county,” said plant operator Roxanna Chomas. “They need to know what happens when they flush the potty!”

Chomas and other city officials worked closely with Flathead EC’s energy services supervisor, Don Newton, for more than four years as contractors replaced the 50-year-old system of lagoons with anerobic digesters and digital controls.

The new system is expected to meet expanding community needs well into the middle of the century while eliminating many known or potential problems common among the more than 16,000 sewage treatment plants operating in the United States.

“It takes in raw sewage, it draws off that clear water, and it’s a very quick process,” Chomas recently told reporters. “It’s very quick, very instantaneous. And it’s all governed by instrumentation. It doesn’t smell at all; there’s no odor from the lagoons.”

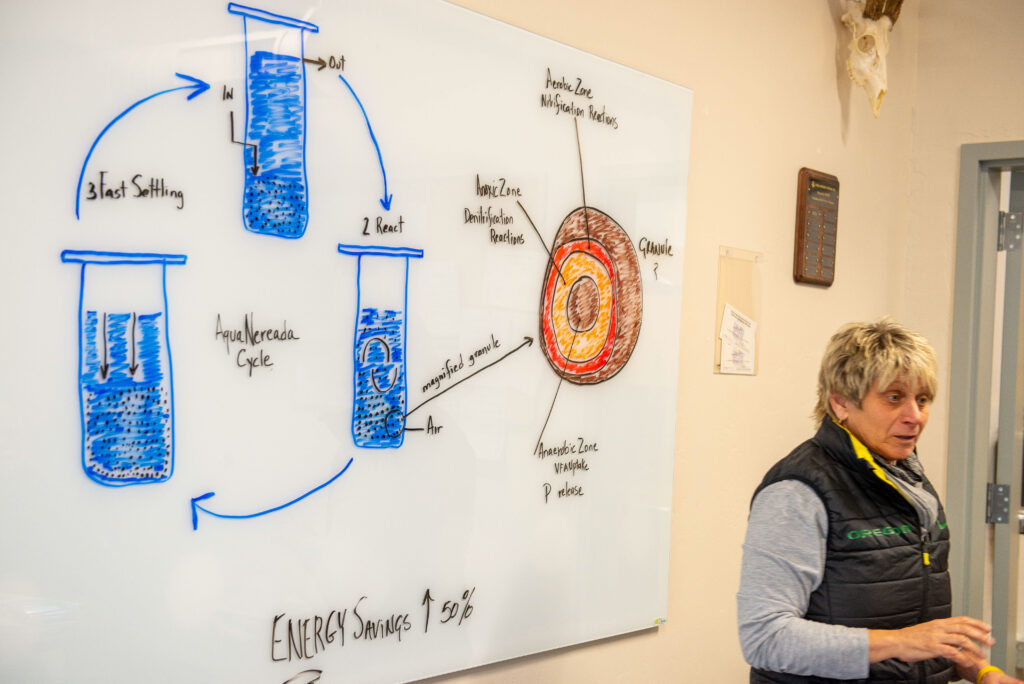

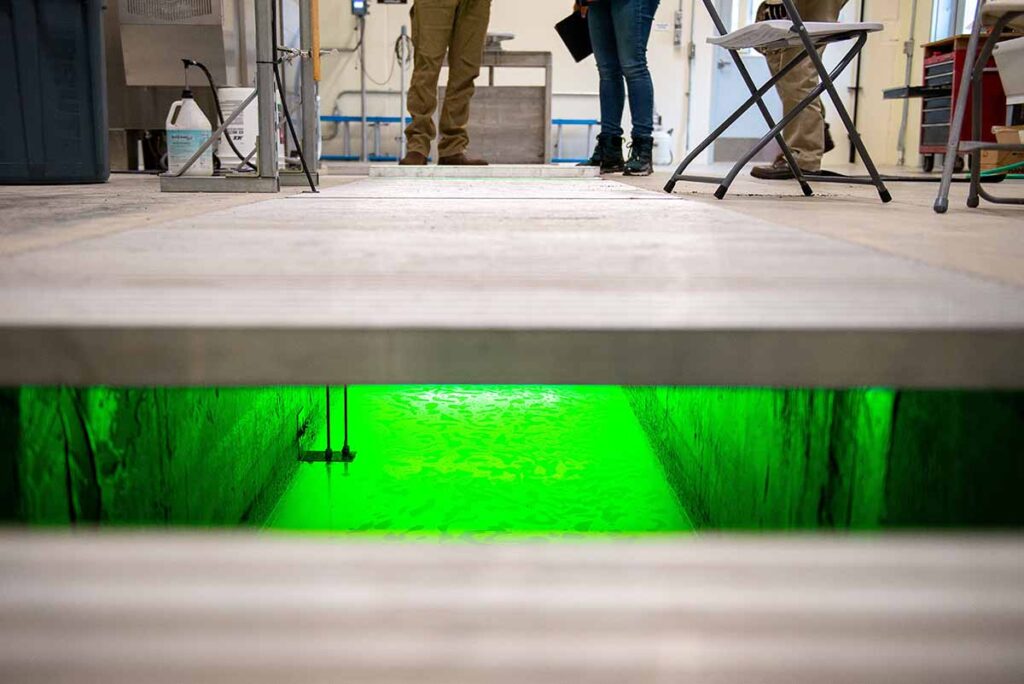

The new plant uses ultraviolet light and granulated microbes shifted through a series of batch tanks to filter and degrade solids. It replaces three lagoons that required constant mechanical stirring with a much more efficient process to drain and remove sludge.

Newton, who frequently works with the co-op’s institutional, industrial and commercial accountholders, studied up on wastewater treatment and called on expertise from the co-op’s wholesale power provider.

Bonneville Power Administration offers economic incentives, in the form of power cost rebates, for energy efficiency improvements that reduce the overall load on its system. Bonneville’s Energy Smart Industrial Program produced about $400 million in energy savings across its eight-state operational region in the past 10 years.

“Clean water is something that everybody wants, and we want that water treated energy efficiently, so it consumes less power,” said Newton. “If we have to buy less wholesale electricity, we can get it at lower cost, then we pass that on to our co-op members.”

While sewage treatment is an essential service, siting and environmental impact remain major concerns. That’s particularly true in areas known for water recreation, including boating, fishing and paddleboarding, which helps drive tourism growth and the development of vacation property. In the past five years, the co-op has added about 10,000 new accounts and now serves about 80,000 meters.

“Flathead Lake is one of the cleanest lakes in the country, so maintaining water quality is a high priority,” said Newton, adding that the system can shift power-intensive processes to off-peak periods when rates are lower. “Noise reduction and very little smell is appreciated by close neighbors.”

The $24 million project, one of four such U.S. plants now using the technology, is expected to reduce electricity usage by nearly 570 kilowatt-hours annually at current levels. Two 40 horsepower pumps that operate 24/7 consume far less electricity than the mechanical systems they replaced, with excess capacity to handle future growth.

Community interest in the project has been overwhelmingly positive. It not only meets or exceeds current federal and state environmental standards, but it’s also led to talks of repurposing some of the land at the wastewater treatment plant for a new solar array.

“Whitefish is not likely to need a new sewage treatment plant for at least 40 years, so adding solar power to the facility could offset some of its power needs from the co-op,” said Newton. “Replacing one of the existing lagoons with a solar installation would be a great opportunity.”

Derrill Holly is a staff writer for NRECA.